georgemiller

Publish Date: Wed, 09 Oct 2024, 12:02 PM

A sustainable future for beer

Climate change affects the taste of beer, and firms in the industry need to ensure taste quality is maintained as demand rises. Brewers are also under pressure to be more sustainable in terms of water use, raw materials and packaging emissions. We think investor scrutiny of retailer commitments could help ensure beer is more sustainably enjoyable.

In this issue of #WhyESGMatters, we discuss the climate and environmental issues associated with beer production and what brewers and investors can do to alleviate this impact.

Did you know?

- Beer holds a volume share of 75% in the global alcoholic beverage market.

- An additional 55% primary energy is needed for one litre of beer packaged in glass vs. in aluminum cans.

- 90% of Europe’s aromatic hop field area is located in Slovenia, Germany and Czech Republic.

- Europe supplies 50-63% of hops globally.

- The average alpha acid content in hops decreased by 34.8% in Celje (Slovenia) between 1971 and 2018.

- Beer production accounts for 5% of the UK's total water demand.

Did you know? Alpha acids are chemical compounds found in the hop plant, which are the source of bitterness, aroma and flavour in beer. Bitter hops have a higher alpha acid content and are generally used to extract bitterness. Aroma or finishing hops have a lower alpha acid percentage, but they contribute to the overall flavour profile. Changes in alpha acids affect the quality of aroma hops, which has an impact on beer’s flavour.

Source: M Mozny et al., Climate-induced decline in the quality and quantity of European hops calls for immediate adaptation measures, Nature Communication, 10 October 2023; European Commission, Crop productions and plant-based products: hops and Hop report for the harvest year 2022; D Amienyo, A Azapagic, Life cycle environmental impacts and costs of beer production and consumption in the UK, The International Journal of Life Cycle Assessment, 2016, World Spirit Alliance, Spirits: Global Economic Impact study 2024.

Climate change and beer

Beer is one of the most popular drinks globally, accounting for 75% of total beverage alcohol volumes, compared to 10.4% for wine, and 9.9% for spirits. The beer industry sits just below spirits in terms of consumer spend, representing 40% of the alcoholic beverage market value. China, the US, and Brazil lead beer market share, accounting for 21.9%, 10.6%, and 7.8% of sales, respectively as of 2022, but Czechs consume the most beer per capita, over 6x China and 3x US, at 189 litres per year.

Will climate change take the taste and aroma away?

Hops: The growing consumer preference for beer flavours, which depends on high-quality hops, has led to increased focus on the impact of climate change on beer brewing. A recent study by the Czech Academy of Sciences and Cambridge University compared European aroma hops during two periods, 1971–1994 and 1995-2018, and found that rising temperatures associated with climate change delayed the start of the hop-growing season by 13 days from 1970 to 2018. This pushed back the critical ripening period towards the warmer part of the season, lowering the alpha acid content in hops and impacting the aroma and flavour of beer.

Climate change is likely to continue to impact European and other top hop-growing regions globally, such as the US (Idaho, Oregon, and Washington), China (Xinjiang and Gansu) and Australia (Tasmania and Victoria). For example a decline of 20-31% in alpha acid content is anticipated in Europe by 2050, while overall yields are expected to shrink by 4-18%. Given that all G20 countries have seen rising temperatures, we expect hop cultivation in these other markets to face similar challenges.

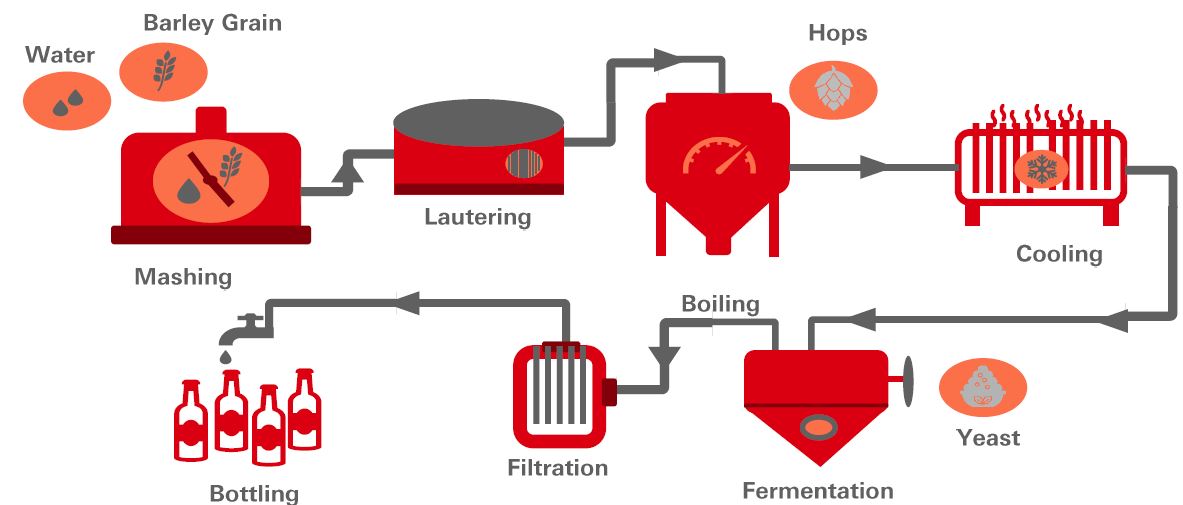

Beer production process

Note: some techniques may vary, e.g., hops may be added at various stages of the process, such as mash hopping and dry hoping.

Source: HSBC, Britannica.

Malted barley: Climate change is also likely to affect malted barley crops, with big implications for the beer industry, given malt provides sugars responsible for alcohol concentration and proteins required for beer’s foaming properties. Indeed, one study shows that most of today’s barley harvesting areas will get warmer and dryer, resulting in sharp declines in yields, by 3-17%, depending on the environment. Research also suggests that increased temperatures and heat intensity can lead to significant rises in grain protein concentration, which reduces the starch concentration and enzymes necessary for high-quality malt and good beer production.

What does this mean for the sector?

We think investors should consider how hop and barley farmers, as well as firms in the sector, implement adaptation measures to ensure availability of high-quality crops. For example, some hop farmers are relocating their gardens to higher elevations and valley locations with higher water tables. They’re also building irrigation systems or protective shading structures and breeding more drought resistant varieties.

Some commentators suggest that, ultimately, hop growing is likely to move to cooler locations, even such as Finland or Norway, due to cost considerations; this adaptation measure is proving to be effective in wine industry. For barley, similar adaptation measures can be done; researchers are also working on new strains of barley that can be grown in different conditions while maintaining malt brewing quality, such as ‘winter ready’ varietals.

The environment and beer

Throughout the lifecycle of beer, sustainability issues exist in the cultivation of raw materials, the production of beer by breweries, and in the packaging and delivering of beers to stores or other places. We discuss three key environmental impacts of beer below.

Water

Water is an essential component in farming beer’s key ingredients, barley and hops. According to the Water Footprint Network, malted barley required to produce one litre of beer needs nearly 300 litres of water. Water is also key in beer’s production processes, from the mashing of grains to washing and cleaning equipment after each batch is completed. The brewing stage itself consumes, on average, between 4-7 litres of water per litre of beer in smaller craft breweries. In the UK alone, the production of beer requires 185bn litres annually, c5% of the UK’s total water demand.

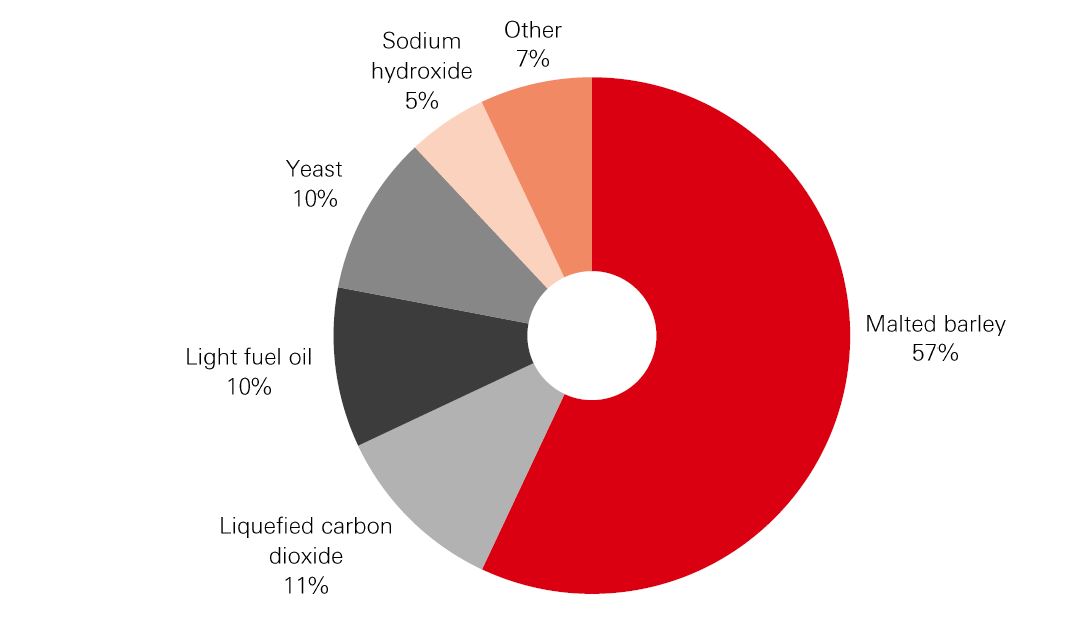

Raw materials

Malted barley encompasses a highly energy-intensive production process, so it’s unsurprising that among the raw materials used to make beer, it makes the biggest contribution to emissions. The use of pesticides and fertilisers not only releases further emissions but also raises biodiversity risks. Globally, 64% of agricultural land is at risk of pesticide pollution, and 34% of high-risk areas are high-biodiversity regions. Hops face similar challenges on top of the energy required to dry them before the boiling process.

Contribution of different materials to beer’s overall emissions from raw materials

Note: Hops are included in ‘Other’

Source: The International Journal of Life Cycle Assessment (2016)

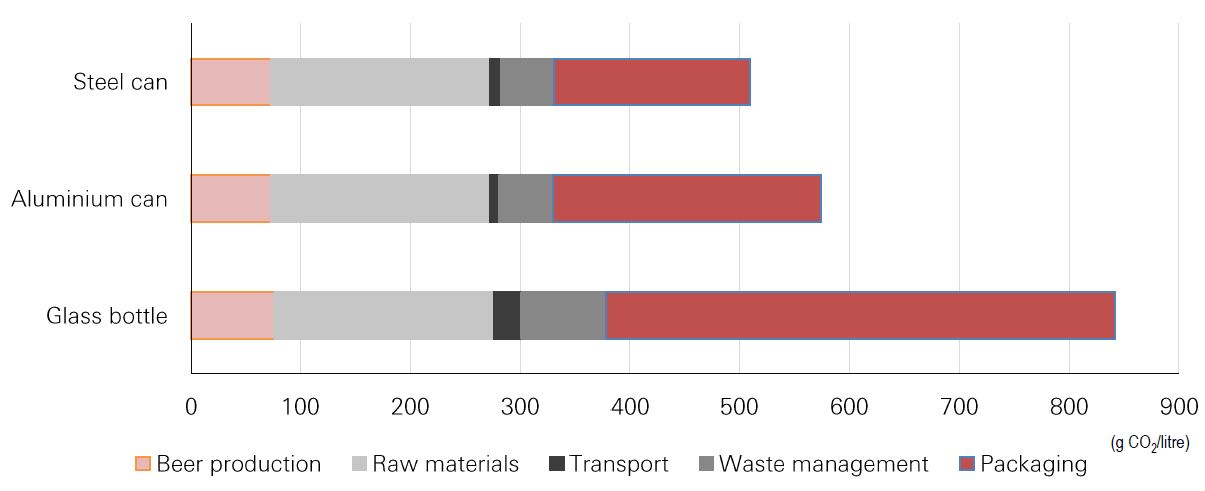

Packaging

Emissions from packaging contribute the largest part of the beer industry’s carbon footprint, which is largely driven by the production and transportation of glass bottles. It’s estimated that one litre of beer packaged in glass requires 55% more primary energy, compared to the same volume in aluminium cans. Recycling and reducing the weight of glass packaging is key: a 10% weight reduction is estimated to save 5% of emissions. At the same time, kegs are the most sustainable option as they can have a useful life of more than 30 years and can be reused more than 150 times before being recycled.

Emissions intensity of beer by packaging and life cycle stage

Source: The International Journal of Life Cycle Assessment.

Addressing sustainability issues

Recent years have seen the rise of carbon-neutral and net-zero breweries. Carbon neutral breweries emphasise the use of carbon offsets, conversely, net-zero breweries take a more proactive approach by addressing emissions across production and supply chains, integrating renewable energy sources and efficient technologies.

Brew without the buzz

With the rise of health-conscious consumers, a rising number of consumers chooses non-alcoholic beverages. According to a 2023 UK survey, 44% of individuals aged 18-24 consider themselves either occasional or regular drinkers of non-alcohol alternatives, and 33% consider themselves non-drinkers. The industry is catching the drift: popular beer brands have started producing low and non-alcohol beers. Non-alcoholic beers require less processing and resources than alcoholic beers and are therefore more sustainable. But the environmental impact of barley and hops, which are still key to their flavour, remains significant.

Flavours fading for craft brewers

We think beer lovers should be aware that these flavoured or hop-forward beers come with a higher environmental impact; they require more aroma hops and are often more water and space intensive than other hop varietals. For example, in the US, it takes c70% more land and water to produce one kilogram of aroma hop pellets than for alpha hop pellets.

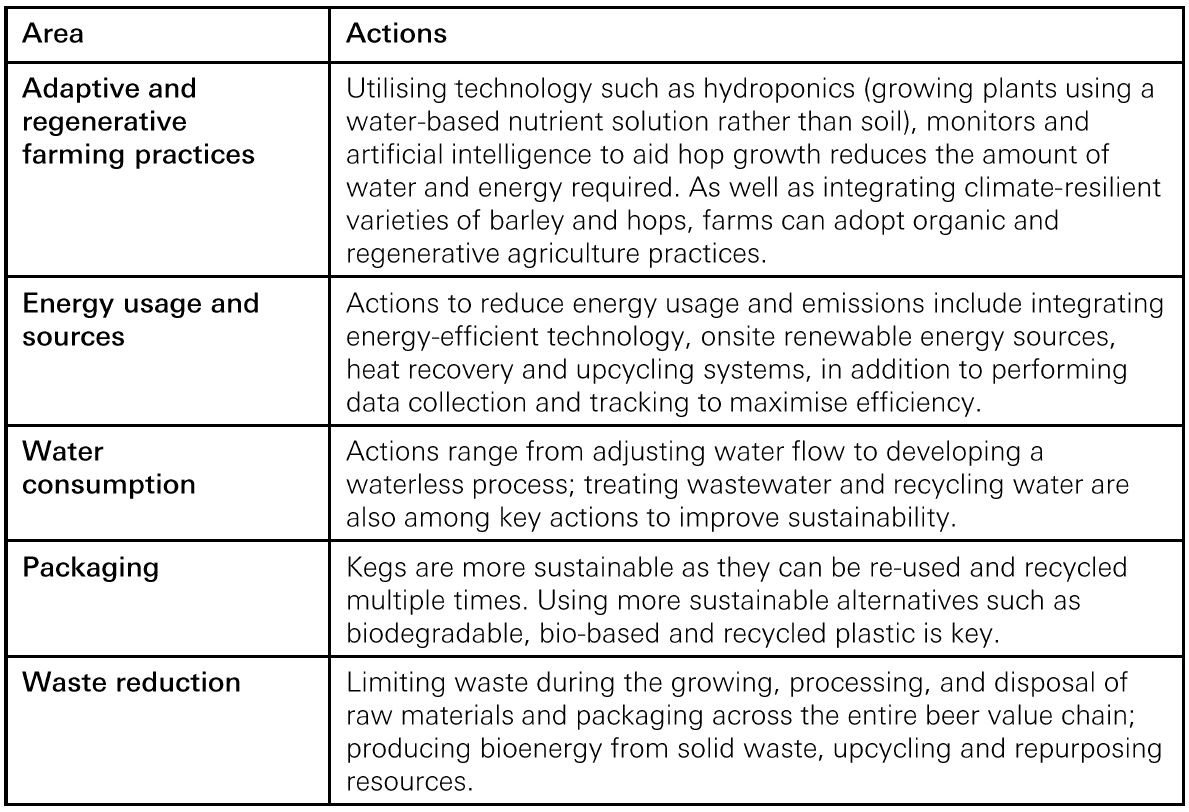

Actions towards sustainable beer production

Source: HSBC; Responsible Brewing: An Introduction to Water, Energy, and Waste Management in Breweries, Medium, 08 July 2023; R Nieto-Villegas et al., Effects on beer attribute preferences of consumers’ attitudes towards sustainability: The case of craft beer and beer packaging, Journal of Agriculture and Food Research, March 2024.

4. Conclusion

As climate change continues to impact the beer sector, we think investors should also continue to scrutinise companies’ sustainability commitments in the beer industry; future improvements should focus on the raw materials stage, especially malted barley, as well as packaging and water use. An increased focus on adaptation measures is also required to meet beer demand without reducing its quality. We believe that over time, investors input could help make beer more sustainably enjoyable.

https://www.hsbc.com.my/wealth/insights/esg/why-esg-matters/2024-08-20/