georgemiller

Publish Date: Mon, 21 Oct 2024, 07:04 AM

Key takeaways

- Customer pressure and regulations are driving demand for green alternatives to traditional plastic materials.

- Yet, the terminology around alternative plastics is confusing and can easily lead to consumer misperception.

- We look at 4 key myths of alternative plastics nomenclature; we think better labelling and consumer education could help.

Customer pressure and regulations are driving demand for green alternatives to traditional plastic materials. These materials are generally perceived to be eco-friendly alternatives to conventional plastic. However, the terminology around alternative plastics is confusing and can easily lead to consumer misperceptions on their sustainability.

In this issue of #WhyESGMatters, we look at four key myths surrounding alternative plastic nomenclature. We explain why investors should think not only about creating plastic alternatives, but about how to encourage a circular economy mindset. This can include better labelling and consumer education.

Did you know?

- European Bioplastics expects global bioplastics to grow at 22% annually until 2028.

- Packaging is the largest end market for plastics, accounting for over 35% of the total c300m tonne annual market.

- Products with the OK Biobased certified label mean they only have at least 20% biobased materials.

- An Australian survey found only 7.7% of respondents correctly rejected the statement that all bioplastics are biodegradable.

- Even reaching a 25% recycled target for PET by 2030 would require a fivefold increase in recycling capacity.

- A material classified as “compostable” will likely only biodegrade in an industrial composting, not your at home composter.

Source: European Bioplastics, Leela Dilkes-Hoffman, et. Al., Public attitudes towards bioplastics – knowledge, perception and end-of-life management, Resources, Conservation and Recycling, 2019, HSBC estimates.

The alternative plastic pivot

Not quite plastic

The pressure to reduce plastic waste, especially from single-use plastics, is mounting on corporates from regulators, investors and consumers. Among elimination and reuse solutions, companies are investing in innovative “green” alternative plastics, sometimes called bioplastics, that look and feel like traditional plastic but are made from biomass and/or have biodegradable properties – think compostable utensils and biobased water bottles. These materials are generally perceived to be eco-friendly alternatives to conventional plastics by reducing fossil fuel use, greenhouse gas (GHG) emissions and/or plastic pollution.

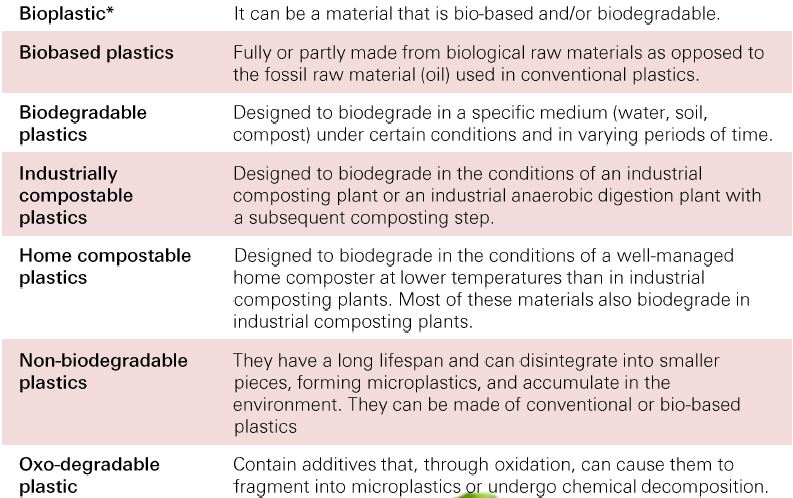

Overview of alternative plastics: Important terms

* For the purpose of this report we define these alternative plastic key terms according to the European Environmental Agency. However, there’s no globally recognised definition for these terms and this has led to widespread confusion by the general public on these materials.

Source: European Environment Agency

Myths versus reality

Myth 1: biobased means biobased

The myth

The reality

It’s all in the mix: Biomass and petroleum sources are often mixed to maintain the durability and quality associated with traditional plastics. There is no universally agreed-upon threshold to define the minimum biobased content needed for a material to be classified as biobased, and the existing certified labels often have low biobased thresholds.

For example, the USDA BioPreferred labelling programme certifies products which meet a minimum biobased content requirement of 25%. Similarly, products with the OK Biobased certified label, often used in the EU, indicate that they have at least 20% biobased materials. Manufacturers often self-label products with biobased terminology, which brings little transparency to the actual biomass content. Other terminology like “bioplastic” “plant-based” and “renewable materials” are also used interchangeably with “biobased” on packaging, adding confusion to customers.

Not all biobased products are created equally. The biomass source, the production process, and the final properties of the material can all have varying environmental impacts. It’s important to consider that biobased terminology isn’t always indicative of environmental impacts.

Myth 2: Biobased means biodegradable

The myth

The reality

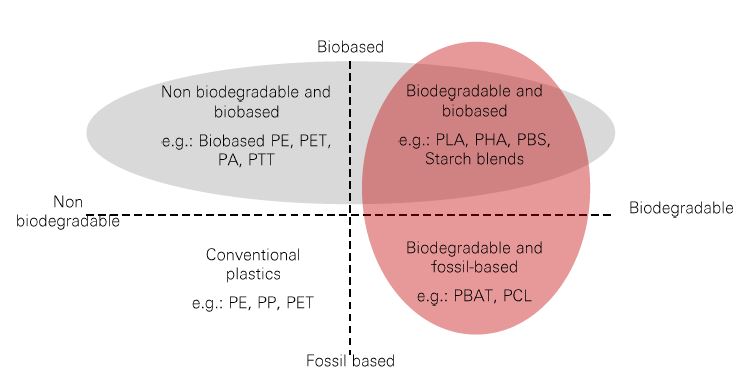

It’s all down to chemistry: In fact, on a molecular level, many biobased plastics are identical to their fossil fuel alternatives and last just as long in nature. Whether these non-biodegradable biobased plastics are recyclable depends on their chemical composition. For example, some biobased (non-biodegradable) materials can be recycled through current collection infrastructure, while others need their own specialised recycling process. It’s crucial to keep in mind that just because a material is biobased doesn’t mean it’s biodegradable, and vice versa.

Biobased packaging isn’t always biodegradable

Source: Bio-plastics Europe, HSBC

Myth 3: Biodegradable means compostable

The myth

The reality

Try this one at an industrial facility: The term “biodegradable” gives no parameters for how quickly and under what conditions a material can biodegrade. Therefore, regulators across the globe are promoting the use of “compostable” terminology to describe alternative packaging – which means a product meets the requirements to biodegrade under the conditions associated with an industrial composting facility. Contrary to an at-home composter, these facilities expose the material to high temperatures and certain microbes essential for biodegradation.

And now, the small print: Currently, many countries have adopted compostability standards for alternative plastics. These include the International Organisation for Standardisation (ISO) international benchmark for compostable plastics (ISO 17088), in addition to country-specific standards, such as ASTM 6400 in the US and EN 13432 in the EU. Generally speaking, standards classify a material as “compostable” if a minimum of 90% of the material can biodegrade in an industrial compost environment within 6 months.

Myth 4: Compostable means compostable

The myth

The reality

Don’t try this one at home: As discussed in myth three, 3rd party certified industrial composting labels are available, but this doesn’t mean that such packaging can be thrown into home or community composting facilities. Although you may find some alternative packaging labelled as ‘home compostable’, the varying environments within home composting equipment provide no guarantee that these materials will fully degrade.

The take-back that isn’t: Limited access to industrial composting facilities and confusion between words like “compostable”, “home compostable” and “industrial compostable” can bring challenges to the disposal of alternative plastic materials. A UK study showed that 60% of sampled items, which were attempted to be home-compost by citizens, weren’t certified for home processing. As a result, many composting facilities choose not to take compostable packaging materials due to concerns about potential contamination of compost with chemicals in packaging and inadequate product labelling being insufficient to ensure packaging is certified compostable.

Making plastic less dramatic

Reimagining plastics

The emerging alternative plastic industry not only faces challenges in integrating sustainable practices, but also in production scale and cost constraints. However, the landscape around alternative plastics is rapidly evolving – there are a growing number of materials, applications and products entering the market. We think scientific advancements and growing international commitments to reducing plastics will help drive innovation.

In a collective initiative organised by Planet Tracker, investors with a total USD6.8trn in assets called on petrochemical companies to reduce fossil fuel reliance and eliminate toxic chemicals in plastics. Additionally, the 5th session of the Intergovernmental Negotiating Committee, which aims at developing an international legally binding instrument on plastic pollution, will happen later this year – putting plastics on the global agenda.

Raising the bar on corporate accountability

Many companies have set goals to replace their single-use plastics with alternatives. Nonetheless, given the opaque sustainability of these “green” plastics, we think companies need to better understand their green packaging claims and build guardrails to avoid misleading consumers. Key company considerations include:

Identifying purpose – It’s essential to have a clear understanding of packaging claims and supply chain implications. Additionally, companies should assess whether the decision to use alternative plastics aligns with their strategic objectives, compared to other plastic solution, e.g. elimination and reuse.

Consumer education – Whether there’s clear consumer awareness of products and their sustainable uses. This includes providing information about how materials can be properly disposed of to have the most sustainable impact.

Labelling – Understanding the certification and standards in operating regions and providing credible third-party labels that bring integrity and transparency to the material.

Waste infrastructure – Whether waste infrastructure is available to their customer base, and/or how they can promote more efficient recycling and composting systems.

Conclusion

Alternative plastics can be potential solution to the plastics problem, addressing their associated GHG emissions and waste. However, as the market for alternative plastics matures, it’s crucial to address the complexities of sustainability and consumer education to ensure that the potential environmental benefits of these can be fully realised. We think companies and investors should focus not only on creating plastic alternatives, but also on encouraging a circular economy mindset, looking for ways to reduce, reuse, and recycle plastics, as well as how readily plastics can be broken down in a non-harmful, non-toxic and cost-effective manner.

We also expect to see more regulations around product labelling, which will provide customers with better clarity. Companies that choose to use alternative plastics who align with verified third-party labelling, promote consumer education, and consider readily available waste infrastructure, give themselves the best chance to take advantage of the environmental benefits of alternative plastics.

https://www.hsbc.com.my/wealth/insights/esg/why-esg-matters/2024-10-09/